-

Geotube

-

Geogrid

-

Nonwoven Geotextile

-

Woven Geotexitle

-

Nonwoven Geo Bag

-

Geosynthetics Clay Liner

-

Anti Grass Cloth

-

Plastic Grass Grid

-

Drainage Board

-

Adjustable Pedestal

-

Composite Geomembrane

-

Tarpaulin

-

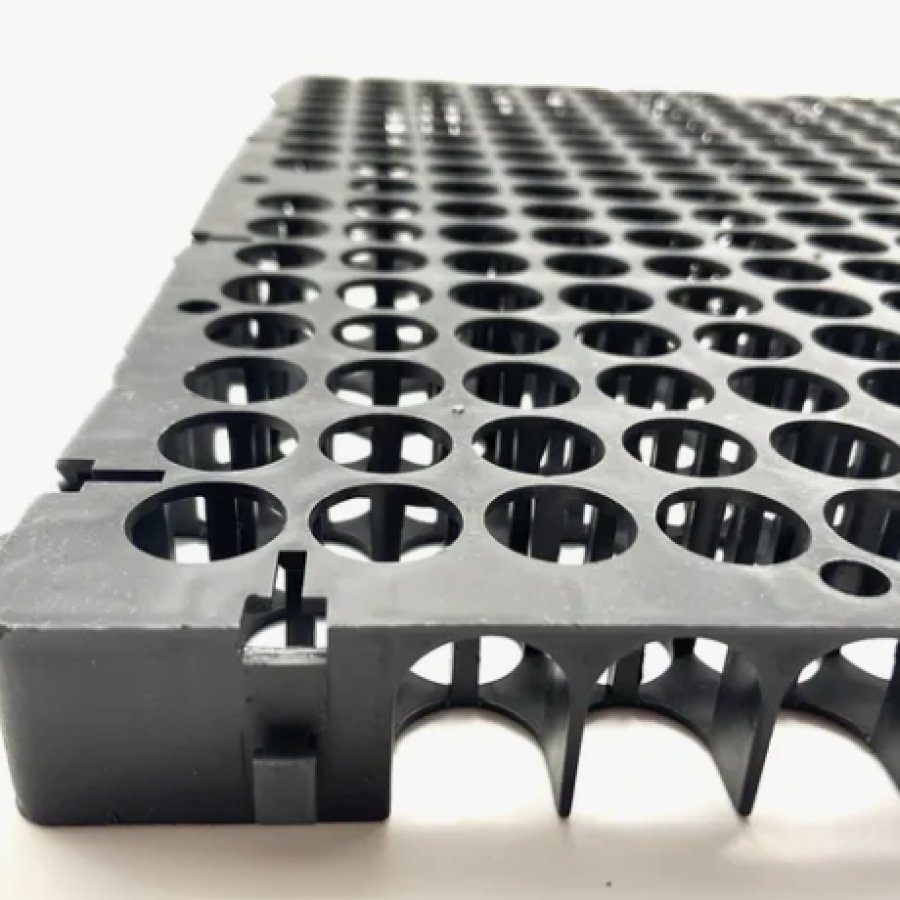

Drainage Cell

-

Road Crack Sealing Tape

-

Geographic Grid

-

Geomembrane welding machine

-

Three Dimensional Geomat

-

Composite Geonet

-

Asphalt cold patch

-

HDPE Geocell

-

Geomembrane

Drainage Cell is a lightweight, efficient and multifunctional drainage product used in foundation drainage, tunnel lining, slope protection, underground structure drainage and other projects. It usually consists of a high-strength plastic frame structure as the internal skeleton, filled with gravel, pebbles, sintered ceramsite or synthetic filter material, and wrapped with a permeable non-woven geotextile or woven mesh to form a complete structure, with good water collection, water conduction, filtration and compression resistance.

Product structure

Skeleton material: high-density polyethylene (HDPE), polypropylene (PP)

Filling material: crushed stone, volcanic rock, sintered filter material, plastic hollow ball, etc.;

Coating layer: PET/PP non-woven geotextile, PE mesh bag or woven cloth, with filtering and protective functions.

ITEM | Unit | CU50 |

Size | mm | 500*500*30 |

Material | Polypropylene | |

Dimple Height | mm | 30 |

Compressive Strength | KPA | ≥140 |

Longitudinal Flow Capacity | cm³/s/cm | ≥25 |

Storage Capacity | L/㎡ | 3 |

Surface Void Area | % | ≥67 |

Internal Void Area | % | ≥95 |

Service Temperature | ℃ | -20 - 120 |

Product features

Lightweight and high strength: light overall weight, easy to transport and carry;

Convenient construction: modular structure, quick assembly on site;

Efficient drainage: porous materials have excellent water permeability and strong drainage capacity;

Strong corrosion resistance: can be buried in groundwater and acid-base soil for a long time;

Customizable specifications: size, outer packaging materials, and fillings can be customized according to the project.

Application areas

Tunnel drainage system: circumferential and longitudinal drainage to protect lining concrete;

High embankment road slope: slope drainage to prevent landslides and softening;

Underground buildings: basement, subway foundation pit side wall drainage system;

Landscaping: water collection and diversion system in planting areas to prevent water accumulation;

Roadbed drainage: replace gravel blind ditch to improve drainage efficiency;

Landfill drainage layer: used in combination with geomembrane;

Drainage on the back of artificial lakes and retaining walls: control hydrostatic pressure.

Shipping scenario:

Logistics and transportation: Use professional logistics and transportation methods to ensure that the products are delivered to customers safely and promptly.

On-site guidance: Provide professional on-site guidance services to assist customers in product laying and construction.

Packaging

To meet the needs of transportation, loading and unloading, and warehousing, drainage cage products adopt the following standard or customizable packaging methods:

Standard packaging

Bundle packaging: multiple drainage cages are bundled in parallel and wrapped in PE woven bags;

Pallet stacking: neatly stacked on wooden pallets/plastic pallets, which is convenient for forklift loading and unloading;

Bulk transportation: suitable for direct supply to short-distance construction sites, saving unpacking time.

Sea freight export packaging

Heat shrink film + strapping tape: ensure moisture and collision protection during sea transportation;

Carton lining or PE bag sealing: improve cleanliness and cargo integrity;

Label/QR code: Each product is accompanied by model, specification, batch number, quantity information, and language and LOGO can be customized according to customer requirements.

Special instructions

Packaging can be classified according to project number and construction sequence;

One-to-one labeling and installation diagrams can be provided;

Customized outer box and printed outer cloth service are provided (MOQ minimum order).

FAQ;

How much pressure can the drainage cage withstand? Is it easy to deform?

Answer: High-quality drainage cages use high-strength HDPE or galvanized steel wire as the skeleton material, and its compressive strength can reach 100-400kPa, which is suitable for general fill, traffic load and even the construction environment behind the tunnel. As long as the construction is reasonable, it is not easy to deform or collapse.

Can the size and shape of the drainage cage be customized?

Answer: Yes. We support customization of the following parameters:

Length: 0.5m-3m;

Diameter/width: 100mm-600mm;

Structural shape: round, square, U-shaped, etc.;

Wrapping type: non-woven fabric, woven fabric, mesh bag, etc.;

Filling type: crushed stone, ceramsite, plastic ball, etc.

Will the wrapping layer of the drainage cage be broken by water flow or blocked by soil?

Answer: No. The outer covering material of the drainage cage is a special geotextile or woven mesh, which has good tensile strength and durability, and has an appropriate pore size, which can effectively filter fine particles and prevent blockage and breakage.

What should be paid attention to during transportation and storage?

Answer:

Drainage cages are light in weight and compact in structure, and can be stacked for transportation;

PE film + strapping or pallet loading is recommended for packaging;

Storage should be kept away from direct sunlight for a long time, and it is recommended to be placed in a cool and dry place;

Prevent sharp objects from puncturing the outer geotextile.

Do you provide OEM service?

Answer: Of course. We can provide the following according to customer needs:

LOGO customization;

Packing bag printing;

Export box labeling;

Exclusive instruction manual or construction manual printing.

Drainage Cell

Drainage Cell

Drainage Cell is a lightweight, efficient and multifunctional drainage product used in foundation drainage, tunnel lining, slope protection, underground structure drainage and other projects. It usually consists of a high-strength plastic frame structure as the internal skeleton, filled with gravel, pebbles, sintered ceramsite or synthetic filter material, and wrapped with a permeable non-woven geotextile or woven mesh to form a complete structure, with good water collection, water conduction, filtration and compression resistance.