-

Geotube

-

Geogrid

-

Nonwoven Geotextile

-

Woven Geotexitle

-

Nonwoven Geo Bag

-

Geosynthetics Clay Liner

-

Anti Grass Cloth

-

Plastic Grass Grid

-

Drainage Board

-

Adjustable Pedestal

-

Composite Geomembrane

-

Tarpaulin

-

Drainage Cell

-

Road Crack Sealing Tape

-

Geographic Grid

-

Geomembrane welding machine

-

Three Dimensional Geomat

-

Composite Geonet

-

Asphalt cold patch

-

HDPE Geocell

-

Geomembrane

Biaxial Green Geogrid is a geosynthetic material made of polypropylene (PP) or high-density polyethylene (HDPE) as the main raw material, which is formed by extrusion, punching, and longitudinal and transverse stretching. Its structure is a regular mesh, with balanced tensile strength in both longitudinal and transverse directions, and uses environmentally friendly green pigments.

Features

Bidirectional force: balanced longitudinal and transverse tensile strength, effectively disperse the load, and improve the overall stability of the foundation.

Green and environmentally friendly: non-toxic green masterbatch is used, no heavy metals are added, and it meets the requirements of environmental protection projects.

Corrosion resistance and aging resistance: acid and alkali resistance, microbial erosion resistance, suitable for various complex geological environments.

Stable structure: uniform mesh size, strong bite force with sand and gravel and other fillers, improving the overall bearing performance.

Easy construction: easy laying and simple overlap, which can save construction time and labor costs.

Item |

Test Method | Unit | PBX1515 | PBX2020 | PBX3030 | PBX4040 | PBX5050 | |||||

MD | TD | MD | TD | MD | TD | MD | TD | MD | TD | |||

Polymer | - | - | PP | |||||||||

Minimum Carbon Black | ASTM D 4218 | % | 2 | |||||||||

Tensile Strength | ASTM D 6637 | kN/m | 15 | 15 | 20 | 20 | 30 | 30 | 40 | 40 | 50 | 50 |

Tensile Strength @ 2% Strain | ASTM D 6637 | kN/m | 5 | 5 | 7 | 7 | 10.5 | 10.5 | 14 | 14 | 17.5 | 17.5 |

Tensile Strength @ 5% Strain | ASTM D 6637 | kN/m | 10.5 | 10.5 | 14 | 14 | 21 | 21 | 28 | 28 | 35 | 35 |

Elongation | ASTM D 6637 | % | 13 | 13 | 13 | 13 | 13 | 13 | 13 | 13 | 13 | 13 |

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 | 93 | 93 | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 7748 | mg-cm | 250,000 | 750,000 | 2,000,000 | 4,800,000 | 8,000,000 | |||||

Aperture Stability | ASTM D 7864 | m-N/deg | 0.32 | 0.50 | 0.75 | 0.98 | 1.10 | |||||

Aperture Size | - | mm | 38 | 38 | 38 | 38 | 36 | 36 | 35 | 35 | 33 | 33 |

Roll Width | - | m | 3.95 or 5.95 | |||||||||

Roll Length | - | m |

| |||||||||

Application areas

Ecological landscape slope protection: improve the stability of green slopes and take into account the greening effect.

Rural roads and parking lot base reinforcement: increase bearing capacity and prevent sinking and rutting.

Park and wetland trail paving: ensure structural strength while maintaining beautiful landscape.

Retaining wall and retaining wall engineering: improve the overall anti-slip stability of the structure.

Green infrastructure projects: such as ecological channels, green roof reinforcement base, etc.

Customized service:

Specification customization: Mesh size, tensile strength, width and other parameters can be adjusted according to customer needs.

Color selection: Black is the conventional color, and other colors can be customized.

Packaging method: Roll and cut pieces are supported, and identification labels can be added for easy management. Special needs: Special treatments such as anti-UV and anti-aging can be provided to adapt to different working conditions.

Production scenario:

Raw material screening: Use high-quality polypropylene particles to ensure stable product performance.

Extrusion molding: Use high-precision equipment for extrusion and punching to ensure uniform hole diameter.

Stretching process: Biaxial stretching technology improves product strength and makes it more durable.

Quality inspection: Strictly test tensile strength, ductility, and durability to ensure qualified delivery.

Delivery scenario:

Standard packaging: Wrapped in plastic film to prevent dust and moisture to ensure safe transportation.

Efficient logistics: Cooperate with multiple logistics companies to ensure fast delivery to national and overseas markets.

Order tracking: Provide logistics tracking services to ensure that customers are aware of the delivery progress in real time.

Product Certification and Certificates:

ISO 9001 Quality Management System Certification

CE Certification (Applicable to European Market)

SGS, BV, Intertek Third-Party Test Reports

Other specific country or industry standard certifications (customizable)

FAQ:

Q1; What are the conventional specifications of PP bidirectional geogrid?

A1; Common specifications: 15KN, 20KN, 30KN, 40KN, 50KN, etc., which can be customized according to needs.

Q2; What is the difference between PP bidirectional geogrid and other types of geogrid?

A2; PP bidirectional geogrid is mainly used to carry uniformly distributed loads, while unidirectional geogrid is suitable for occasions requiring higher longitudinal strength (such as retaining walls).

Q3; How to choose the appropriate geogrid specifications?

A3; It depends on the geological conditions of the project, load requirements and other factors. It is recommended to consult professional technicians to recommend the appropriate model.

Q4; How to store PP bidirectional geogrid?

A4; It should be stored in a dry and ventilated environment, avoid direct sunlight, and prevent aging.

Q5; Can you provide samples?

A5; Free samples can be provided, but the shipping cost needs to be borne by the customer.

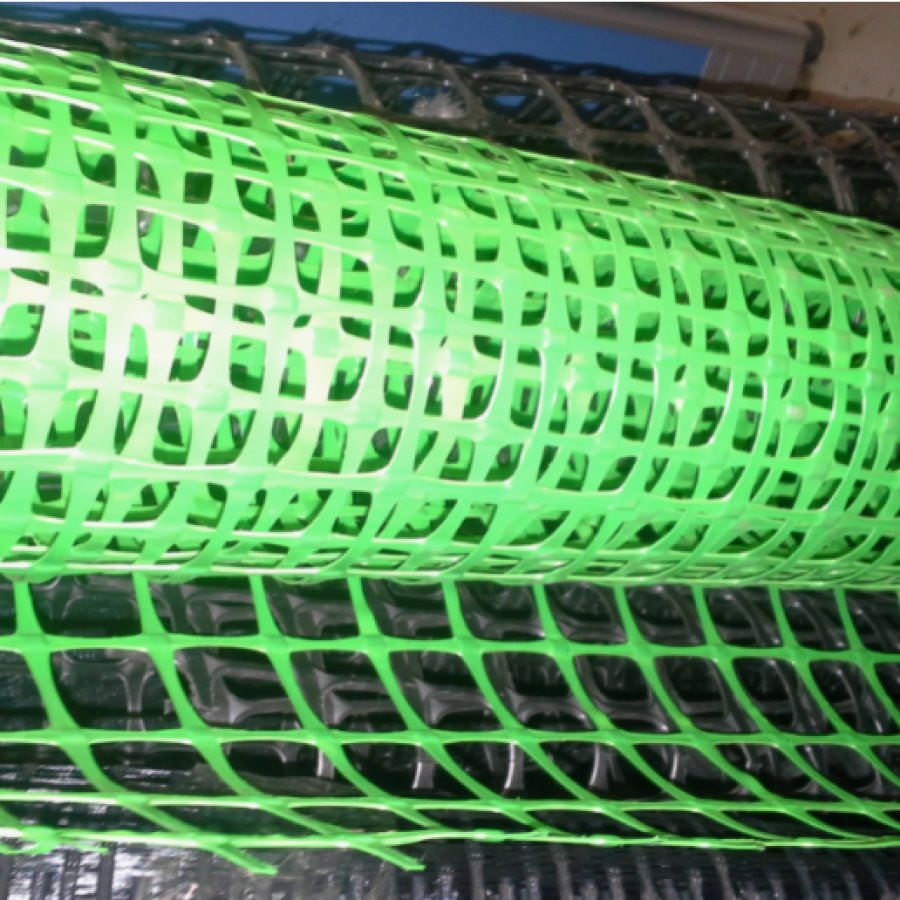

Green PP Biaxial Geogrid

Green PP Biaxial Geogrid

Biaxial Green Geogrid is a geosynthetic material made of polypropylene (PP) or high-density polyethylene (HDPE) as the main raw material, which is formed by extrusion, punching, and longitudinal and transverse stretching. Its structure is a regular mesh, with balanced tensile strength in both longitudinal and transverse directions, and uses environmentally friendly green pigments.

PP Biaxial Geogrid

PP Biaxial Geogrid

PP bidirectional geogrid is a high-strength geosynthetic material made of polypropylene (PP) through extrusion, punching, heating, and longitudinal and transverse stretching. Its main function is to improve the bearing capacity of soil and enhance the stability of roadbed. It is widely used in various infrastructure construction.

Biaxial Plastic Geogrid

Biaxial Plastic Geogrid

PP(Polypropylene) biaxial geogrid is manufactured from PP, it is produced through the process of extruding, punching, heating,longitudinal and transverse stretching.