-

Geotube

-

Geogrid

-

Nonwoven Geotextile

-

Woven Geotexitle

-

Nonwoven Geo Bag

-

Geosynthetics Clay Liner

-

Anti Grass Cloth

-

Plastic Grass Grid

-

Drainage Board

-

Adjustable Pedestal

-

Composite Geomembrane

-

Tarpaulin

-

Drainage Cell

-

Road Crack Sealing Tape

-

Geographic Grid

-

Geomembrane welding machine

-

Three Dimensional Geomat

-

Composite Geonet

-

Asphalt cold patch

-

HDPE Geocell

-

Geomembrane

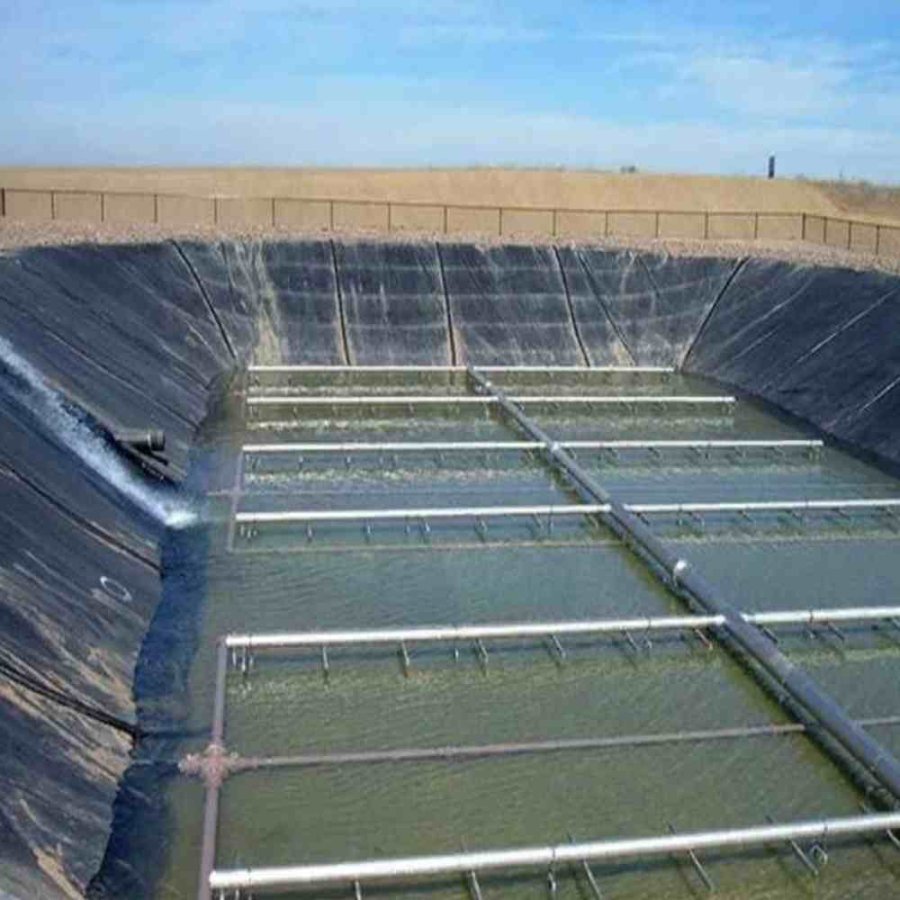

HDPE geomembrane (high-density polyethylene geomembrane) is a waterproof and anti-seepage material made by blowing or calendering process. It has excellent anti-seepage performance, chemical corrosion resistance, aging resistance and mechanical strength, and is widely used in anti-seepage projects such as landfills, reservoirs, artificial lakes, sewage treatment pools, and mine tailings ponds.

Geomembrane solution provider

Customers served: Dubai, Abu Dhabi, Riyadh, Dammam, Jeddah, Sharjah, Mecca, Ajman and other cities

Delivery capacity: Monthly shipments reach more than 5,000 tons

Standard certification: ASTM, GCC specifications, GSO standards, ISO9001, CE certification

Support FOB China port / CIF / Saudi warehouse delivery

Product advantages (tailor-made for the Middle East environment)

Super high temperature resistance; HDPE film can withstand construction and use temperatures above 50°C for a long time without melting or shrinking.

Strong UV and antioxidant capabilities; specially formulated with UV stabilizers, suitable for strong sunlight and sandstorm conditions in Saudi Arabia and the UAE.

Lifespan of more than 50 years; long-term projects, such as industrial pools, landfills, etc.

Easy to weld, high construction efficiency; supports hot melt welding, wedge welding, extrusion welding; provides welding equipment and training support.

Can be used with composite material systems; such as GCL (bentonite liner), geotextile, and drainage board to build a complete anti-seepage system.

Properties | Test Method | GMSH050 | GMSH075 | GMSH100 | GMSH150 | GMSH300 |

■ Thickness | ASTM D5199 | 0.50 mm | 0.75 mm | 1.00 mm | 1.50 mm | 3.00 mm |

■ Density | ASTM D1505 | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc |

Tensile Properties | ||||||

■ Yield strength ■ Break strength ■ Yield elongation ■ Break elongation | ASTM D6693 Type IV

| 7 kN/m 13 kN/m 12% 700% | 11 kN/m 20 kN/m 12% 700% | 15 kN/m 27 kN/m 12% 700% | 22 kN/m 40 kN/m 12% 700% | 41 kN/m 82 kN/m 12% 700% |

■ Tear Resistance | ASTM D1004 | 62 N | 93 N | 125 N | 187 N | 375 N |

■ Puncture Resistance | ASTM D4833 | 160 N | 240 N | 320 N | 480 N | 960 N |

■ Stress Crack Resistance | ASTM D5397 | 500 hrs | 500 hrs | 500 hrs | 500 hrs | 500 hrs |

■ Carbon Black Content | ASTM D1603 | 2.0% | 2.0% | 2.0% | 2.0% | 2.0% |

■ Carbon Black Dispersion | ASTM D5596 | For 10 different views:9 in Categories 1 or 2 and 1 in Category 3 | ||||

■ Oxidative Induction Time (OIT) | ASTM D3895 | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. |

■ UV Resistance High Pressure OIT retained after 1600hrs |

ASTM D5885 |

50% |

50% |

50% |

50% |

50% |

Dimensions | ||||||

■ Roll Width (m) | 7 | 7 | 7 | 7 | 7 | |

■ Roll Length (m) | 420 | 280 | 210 | 140 | 50 | |

Engineering field (especially suitable for the Middle East)

Desert area water pool / irrigation pool / artificial lake anti-seepage

Refinery / oil tank area chemical liquid pool

Temporary ponds and diversion channels for large engineering projects

Saudi mining and tailings yard anti-seepage

Landfill anti-seepage system (used in conjunction with GCL/drainage board)

Greening project, Dubai artificial island shoreline project, wetland protection area

Conventional packaging and export services

International standard packaging: PE film rolls with labels and pallets are optional

Customized specifications: 18m width, 50-200m length are optional

Direct delivery from multiple warehouses: supports delivery from Chinese factories, Dubai Jebel Ali warehouse, Saudi Arabia local warehouse

Trade support: Provide CO, Form E, SASO certification, commodity inspection documents, etc.

Customer Cases

Abu Dhabi Chemical Pool Project, 1.5mm HDPE Membrane 100,000㎡

Saudi Arabia Temporary Liquid Storage Tank, 1.0mm Smooth HDPE Membrane 85,000㎡

Contact us

Free technical consultation and selection recommendations

Project customized material design

One-stop service for export declaration, transportation and after-sales

OEM service / private label customization

WhatsApp / WeChat / Email: 24-hour support

Flexible MOQ, support sample testing and project trial

Shipping scenario

Logistics and transportation: Use professional logistics and transportation methods to ensure that products are delivered to customers safely and promptly.

On-site guidance: Provide professional on-site guidance services to assist customers in product laying and construction.

Certificates:

Product quality certification: Passed ISO9001 quality management system certification, CE certification, etc.

Product test report: Provide product test reports issued by authoritative organizations.

FAQ:

How long is the service life of HDPE geomembrane?

When used under normal conditions, the service life of HDPE geomembrane can reach more than 50 years. If exposed to strong ultraviolet rays for a long time, the service life will be shortened, but the addition of antioxidants and UV stabilizers can significantly extend the service life.

Is HDPE geomembrane resistant to chemical corrosion?

Yes. HDPE geomembrane has excellent chemical stability and can resist corrosion from most acids, alkalis, salts, oils and organic solvents, and is particularly suitable for chemical and mining environments.

What is the difference between HDPE geomembrane and LLDPE geomembrane?

HDPE film is harder and has high tensile strength, which is suitable for long-term projects;

Is HDPE geomembrane environmentally friendly?

Yes. HDPE is a recyclable material, non-toxic and harmless, and is widely used in environmental protection projects such as landfills and sewage treatment plants, which can effectively prevent pollutants from leaking.

How high a temperature can HDPE geomembrane withstand?

The temperature resistance range of HDPE geomembrane is roughly -60℃ to +60℃. It can withstand higher temperatures for a short time, but long-term high temperatures may affect its performance.

Water conservancy project anti-seepage 0.5/0.75mm geomembrane manufacturer

Water conservancy project anti-seepage 0.5/0.75mm geomembrane manufacturer

High-density polyethylene (HDPE) geomembrane has gradually become the mainstream anti-seepage material due to its excellent anti-seepage performance, chemical stability and weather resistance. It has specifications of 0.5mm and 0.75mm thickness and is more widely used in small and medium-sized water conservancy projects and agricultural irrigation systems.

Top Geomembrane Supplier in UAE & Saudi Arabia - ISO Certified

Top Geomembrane Supplier in UAE & Saudi Arabia - ISO Certified

HDPE geomembrane (high-density polyethylene geomembrane) is a waterproof and anti-seepage material made by blowing or calendering process. It has excellent anti-seepage performance, chemical corrosion resistance, aging resistance and mechanical strength, and is widely used in anti-seepage projects such as landfills, reservoirs, artificial lakes, sewage treatment pools, and mine tailings ponds.

HDPE Geomembrane

HDPE Geomembrane

High-density polyethylene (HDPE) geomembrane is a waterproof and seepage-proof material made by blow molding or calendering processes. It boasts excellent seepage prevention performance, chemical corrosion resistance, aging resistance, and mechanical strength, making it suitable for seepage prevention projects in landfills, reservoirs, artificial lakes, sewage treatment ponds, and mine tailings ponds.

Pond water seepage prevention 1.0mm geomembrane liner

Pond water seepage prevention 1.0mm geomembrane liner

Geomembrane liner waterproof and anti-seepage material has high anti-seepage performance, chemical corrosion resistance, aging resistance and mechanical strength. It is widely used in anti-seepage projects such as landfills, reservoirs, artificial lakes, sewage treatment pools, and mine tailings ponds.

Black fish pond protection 1.2/1.5mm ASTM standard geomembrane

Black fish pond protection 1.2/1.5mm ASTM standard geomembrane

Black Fish Pond Protection 1.2/1.5MM ASTM standard geomembrane is a high-strength geosynthetic material specially used for water protection, such as fish ponds, artificial lakes and other water conservancy facilities. It uses high-density polyethylene with excellent anti-seepage and UV resistance, which can effectively prevent water leakage and prevent external pollutants from entering the water.